Thermocouples: The Temperature Sensing Workhorses

Introduction to Thermocouples

Thermocouples are among the most widely used temperature sensors in industrial, scientific, and commercial applications. These robust and versatile devices operate on a simple yet ingenious principle, making them indispensable in environments ranging from home appliances to aerospace engineering.

What is a Thermocouple?

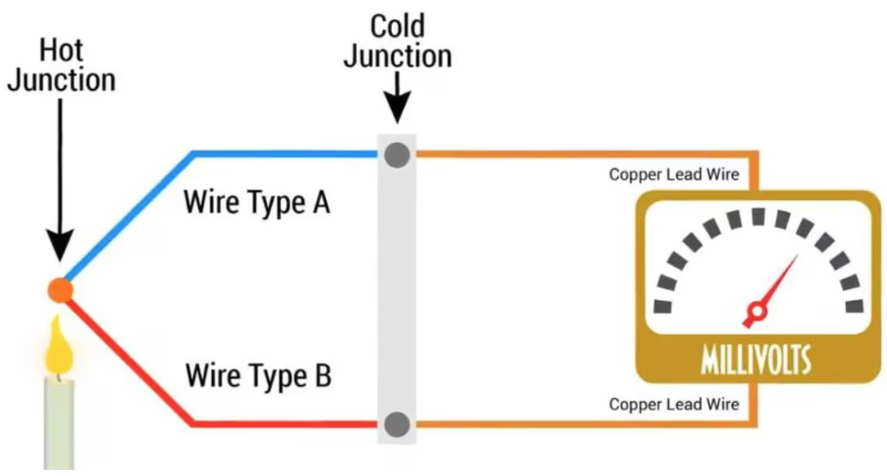

A thermocouple is a temperature-measuring device consisting of two different electrical conductors/wires forming an electrical junction. When the junction experiences a temperature change, it produces a temperature-dependent voltage that can be interpreted to measure temperature.

How Do Thermocouples Work?

When two different wire metals are joined together at both ends and one end is heated,

an electrical current flows through the circuit. If we break this circuit in the

middle, we can measure a voltage (called the Seebeck voltage) that directly relates

to the temperature at the junction and the specific metals used.

In practical terms, this means when the junction between two different metals is

heated or cooled, it produces a voltage that we can measure and use to determine

the temperature. This is the basic principle behind thermocouples, which are widely

used temperature sensors in engineering applications.

The voltage generated is typically small (in the millivolt range) and requires

amplification for practical measurement. The relationship between temperature and

voltage is not perfectly linear but follows predictable patterns that can be calibrated.

Types of Thermocouples

Thermocouples come in various standardized types, each designated by letters and optimized

for different temperature ranges and environments:

- Type K (Chromel–Alumel): The most common general-purpose thermocouple, with a temperature range of -200°C to +1350°C

- Type J (Iron–Constantan): Suitable for vacuum, reducing, or inert environments, with a range of -40°C to +750°C

- Type T (Copper–Constantan): Excellent for low-temperature applications, with a range of -250°C to +350°C

- Type E (Chromel–Constantan): Highest EMF output per degree of all standard thermocouples

- Type N (Nicrosil–Nisil) Designed to be more stable at high temperatures than Type K

- Types R, S, and B:Platinum-based thermocouples for high-temperature applications up to 1800°C

Advantages of Thermocouples

Thermocouples offer several distinct advantages over other temperature sensors:

- Wide temperature range: Can measure from cryogenic temperatures to over 2000°C

- Ruggedness: Withstand vibration, shock, and harsh environments

- Fast response: React quickly to temperature changes

- No need for external power: Self-powered through the Seebeck effect

- Simplicity: No moving parts, simple construction

- Cost-effectiveness: Generally less expensive than other temperature sensors

Advantages of Thermocouples

Despite their advantages, thermocouples have some limitations:

- Lower accuracy: Typically ±0.5°C to ±2.0°C, compared to RTDs or thermistors

- Reference junction compensation:Typically ±0.5°C to ±2.0°C, compared to RTDs or thermistors

- Nonlinearity: The voltage-temperature relationship is not perfectly linear

- Drift over time: Aging and contamination can affect accuracy

- Limited sensitivity: Lower output signals than other sensor types

Thermocouple Probe

A thermocouple probe consists of thermocouple wire housed inside a metallic tube. The wall

of the tube is referred to as the sheath of the probe. Common sheath materials include

stainless steel and Inconel®. Inconel supports higher temperature ranges than stainless

steel, however, stainless steel is often preferred because of its broad chemical compatibility.

For very high temperatures, other exotic sheath materials are also available.

Thermocouples vs. PT-100 Elements: Key Differences

While both thermocouples and PT-100 elements (also known as Platinum Resistance Thermometers or PRTs) are temperature sensing devices, they operate on fundamentally different principles and have distinct characteristics that make each suitable for specific applications.

Operating Principle

Thermocouples:

- Operate based on the Seebeck effect

- Generate a small voltage when two dissimilar metals joined at a junction experience a temperature difference

- Self-powered, producing an electrical output without external power

PT-100 Elements:

- Operate based on the principle that electrical resistance of platinum changes predictably with temperature

- The "100" in PT-100 refers to the resistance value of 100 ohms at 0°C

- Require an external current source to measure the resistance change

Accuracy

Thermocouples:- Generally less accurate (typically ±0.5°C to ±2.0°C)

- Accuracy varies with thermocouple type and quality

- Susceptible to drift over time

PT-100 Elements:

- Significantly more accurate (typically ±0.1°C to ±0.3°C)

- More stable over time with less drift

- Standard reference for many calibration applications

- Class A, B, and 1/10 DIN variants offer different levels of accuracy

Temperature Range

Thermocouples:- Wider temperature range, depending on type

- Type K: -200°C to +1350°C

- Some types can measure up to 2300°C

PT-100 Elements:

- More limited range, typically -200°C to +850°C

- Better performance at lower temperatures

Response Time

Thermocouples:- Generally faster response time to temperature changes

- Smaller thermal mass allows quicker equilibration

PT-100 Elements:

- Typically slower response due to larger thermal mass

- Response time can be improved with thinner film designs

Linearity

Thermocouples:- Non-linear relationship between temperature and output voltage

- Requires complex conversion algorithms or lookup tables

PT-100 Elements:

- Nearly linear relationship between temperature and resistance

- Follows a well-defined equation (Callendar-Van Dusen equation)

Cost

Thermocouples:- Generally less expensive

- Simpler construction and materials

PT-100 Elements:

- Typically more expensive due to platinum content

- More complex signal conditioning required

Size

Thermocouples:- Can be made extremely small (even wire diameter of 0.25mm)

- Junction can be very compact

PT-100 Elements:

- Generally larger due to construction requirements

- Thin-film designs have reduced this difference in recent years

Wire Length Effect

Thermocouples:- Lead wire resistance doesn't affect measurement accuracy

- Extension wires must be of the same thermoelectric materials

PT-100 Elements:

- Lead wire resistance can significantly affect measurement

- Typically requires 3-wire or 4-wire connections to compensate for lead resistance

Applications

Thermocouples:- High-temperature industrial processes

- Situations requiring ruggedness and vibration resistance

- Cost-sensitive applications

- When fast response is critical

PT-100 Elements:

- Precision laboratory applications

- Food and pharmaceutical processes requiring high accuracy

- Environmental monitoring

- Medical applications

- When stability and repeatability are crucial

The choice between a thermocouple and a PT-100 element depends on your specific requirements. Thermocouples excel in harsh environments, wide temperature ranges, and cost-sensitive applications, while PT-100 elements are superior when accuracy, stability, and repeatability are paramount.