Flow Measurement in Process Industry

Introduction to flow measurement

Flow measurement stands as one of the most essential parameters in industrial instrumentation, serving as the backbone of countless processes across diverse sectors including oil and gas, water management, chemical manufacturing, pharmaceuticals, and food production.

Understanding Flow Measurement Basics

Flow measurement involves determining the rate at which a fluid—liquid or gas—moves through a

defined area over time (example a pipe). This seemingly straightforward concept encompasses sophisticated principles

of fluid dynamics, material properties, and instrumentation design.

Flow can be expressed in several ways:

- Volumetric flow rate (e.g., gallons per minute, cubic meters per hour)

- Mass flow rate (e.g., pounds per minute, kilograms per second)

- Velocity (e.g., feet per second, meters per second)

The choice of measurement unit depends on the application requirements and industry standards.

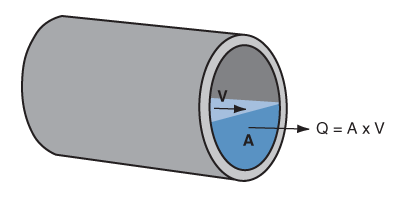

As the image below shows, can we define the volumetric flow rate (basic formula) as Q = A × v.

- Q = volumetric flow rate (m³/s, ft³/s, L/min, GPM)

- A = cross-sectional area (m², ft², in²)

- v = fluid velocity (m/s, ft/s)

Pipe Flow Calculation

For a circular pipe with diameter D, the cross-sectional area is:

A = π × (D/2)² = π × D²/4

Therefore, the volumetric flow rate becomes:

Q = π × D²/4 × v

This allows engineers to calculate flow rates based on pipe dimensions and fluid velocity, or conversely, determine required pipe sizes for desired flow rates.

Flow Profile Considerations

The formula Q = A × v assumes a uniform velocity across the entire cross-section. In reality, fluid velocity varies across the pipe diameter due to:

- Friction at pipe walls causing zero velocity at the boundary

- Maximum velocity occurring at the pipe centerline

- Distribution pattern differences between laminar and turbulent flows

Practical Example

Consider water flowing through a 2-inch (0.0508 m) diameter pipe at an average velocity of 3 m/s:

- Calculate the cross-sectional area: A = π × (0.0508 m)²/4 = 0.00203 m²

- Apply the volumetric flow rate formula: Q = 0.00203 m² × 3 m/s = 0.00608 m³/s

- Convert to more practical units if needed: Q = 0.00608 m³/s × 60 s/min × 1000 L/m³ = 364.8 L/min

For more details on different flow measurement methods, see my other sections here.