Thermowells: The Protective Shield for Temperature Transmitters

Introduction

Temperature measurement is a critical aspect of industrial processes, and thermowells play a vital role in protecting temperature sensors from harsh process conditions. This article explores thermowells, their functions, and the important wake frequency calculations that ensure their reliability.What is a Thermowell?

A thermowell is a protective metal sleeve or pocket that shields

temperature sensors (like thermocouples or RTDs) from direct contact with the

process fluid. Think of it as a protective armor that allows the sensor to measure

temperature while being protected from:

- High pressure

- Corrosive materials

- Abrasive flow

- Physical damage during maintenance

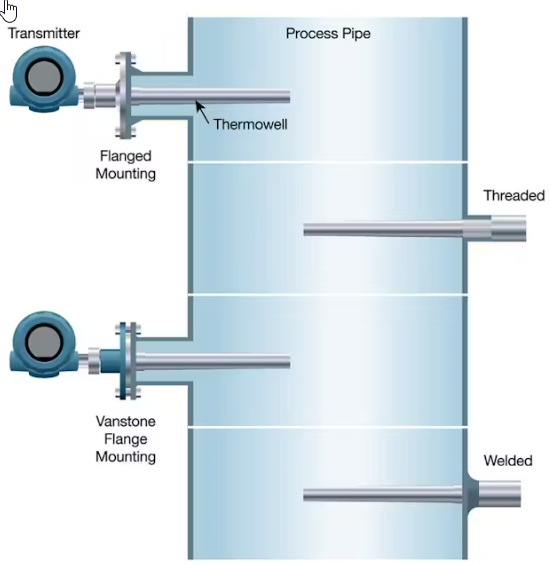

Thermowells are typically installed into pipes or vessels by welding, threading, or flanging, with the temperature sensor inserted inside the thermowell.

Why Do We Need Thermowells?

Without a thermowell, temperature sensors would:

- Wear out quickly in harsh environments

- Be impossible to remove or replace without shutting down the process

- Potentially contaminate the process fluid if damaged

- Be exposed to potentially damaging conditions

Wake Frequency Calculation: The Hidden Challenge

While thermowells provide excellent protection, they face a physical challenge called vortex shedding. This phenomenon occurs when fluid flows around the thermowell, creating alternating vortices (swirling patterns) on opposite sides.

What is Vortex Shedding?

When fluid flows past a thermowell, it creates small whirlpools or vortices that break away

from the thermowell. These vortices form a pattern known as a "vortex street" and detach alternately

from opposite sides of the thermowell.

This alternating vortex formation creates fluctuating pressure that can cause the thermowell to

vibrate. If the frequency of these vibrations matches the natural frequency of the thermowell,

it can lead to resonance.

Why Resonance is Dangerous

Resonance is a phenomenon that occurs when an external force applied to a

system matches that system's natural frequency of vibration, causing the

system to oscillate with increased amplitude. This can lead to dramatic

and sometimes destructive effects.

The Basics of Resonance

At its core, resonance happens when:- A system has a natural frequency at which it tends to vibrate when disturbed

- An external force applies energy to the system at or near that same frequency

- The system absorbs this energy, causing vibrations to grow larger and larger

Think of pushing a child on a swing. If you push at random times, the swing moves erratically. But if you push at precisely the right moment (matching the swing's natural frequency), even small pushes will make the swing go higher and higher.

Natural Frequency

Every physical object has one or more natural frequencies determined by its:- Mass

- Stiffness/elasticity

- Geometry

- Material properties

How Resonance Works

When an external force applies energy at a frequency matching the natural frequency:- The system absorbs energy efficiently

- Each cycle adds to the previous cycle's energy

- The amplitude (size) of the vibration increases

- This continues until damping forces or mechanical failure occur

Resonance occurs when the vortex shedding frequency matches the natural frequency of the thermowell.

When this happens:

- The vibration amplitude increases dramatically

- Metal fatigue develops rapidly

- Eventually, the thermowell can break off completely

This failure would not only lose the temperature measurement but could also release the broken thermowell into the process, potentially causing severe damage to downstream equipment like pumps or valves.

Wake Frequency Calculation: The Safety Check

The wake frequency calculation is essentially a safety check to ensure that resonance won't occur.

It compares:

- The natural frequency of the thermowell (how fast it would naturally vibrate)

- The vortex shedding frequency (how fast vortices form and detach)

A safe design requires these frequencies to be far enough apart to prevent resonance.

The Simplified Wake Frequency Formula

While the complete calculation is complex, here's a simplified explanation of what factors affect the wake frequency:

- Thermowell dimensions: Length, diameter, and wall thickness all affect its natural frequency. A shorter, thicker thermowell has a higher natural frequency.

- properties: The elastic modulus and density of the thermowell material affect how it vibrates.

- Fluid properties: Flow velocity, density, and viscosity of the process fluid affect the vortex shedding frequency.

- Process conditions: Temperature and pressure influence both the fluid and thermowell properties.

Safety Factor

Industry standards (like ASME PTC 19.3 TW) recommend that the ratio between the natural frequency and the vortex shedding frequency should be at least 1.2:1. This safety margin helps ensure that even with process variations, resonance won't occur.

Practical Solutions for Wake Frequency Issues

If calculations show a potential risk of resonance, engineers can:

- Reduce the thermowell length: A shorter thermowell has a higher natural frequency.

- Increase the thermowell diameter: A thicker design is more rigid.

- Use a velocity collar: This special design disrupts the vortex formation pattern.

- Choose a tapered design: Tapered thermowells offer better rigidity with less flow restriction.

- Use a helical design: Special helical thermowells break up vortex formation.

Who Can Perform Thermowell Wake Frequency Calculations

Wake frequency calculations for thermowells require specialized knowledge and expertise. Fortunately, when ordering a thermowell from the manufacturer, you can usually ask them to perform the wake frequency calculation for you.

Conclusion

Thermowells are essential components in industrial temperature measurement, providing protection for sensors

while enabling accurate readings. The wake frequency calculation is a critical safety check that prevents

potentially catastrophic failures due to resonance.

By understanding these principles, instrument engineers can select and install thermowells that provide

reliable temperature measurements while maintaining process safety and integrity.