Block and bleed valves

Introduction

Block and bleed valves are specialized valve assemblies designed to do two important jobs in pipelines. The valves combine two essential functions. Blocking (isolating) sections of a piping system and bleeding (venting or draining) the cavity between isolation points. This dual functionality makes them critical components in industries where process safety and integrity are paramount.The primary purpose of these valves is to create a verified barrier between potentially hazardous process fluids and personnel or sensitive equipment. By incorporating a bleed mechanism, operators can confirm that isolation has been successfully achieved before proceeding with maintenance or other operations

Types of Block and Bleed Configurations

We usually talk about two configurations of block and bleed valves. These two configurations are block and bleed valve (B&B or SB&B), and double block and bleed valves (DB&B).

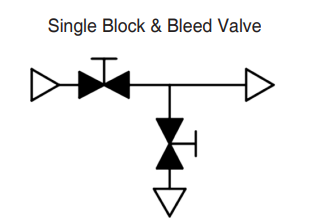

Block and bleed valves (B&B or SB&B)

A Block and Bleed (B&B) or Single Block and Bleed (SB&B) configuration utilizes one block valve and one bleed valve. This simpler arrangement provides a single isolation point with the ability to verify its effectiveness through the bleed function.

The typical components of an SB&B system include:

- One block valve (isolation point)

- Bleed valve (positioned downstream of the block valve)

- Cavity or section between the block valve and the next system component

SB&B systems are more compact and economical than DB&B configurations, making them suitable for applications with space constraints or lower risk profiles. While they don't provide the same level of redundant protection as DB&B systems, they still offer significant safety advantages over standard isolation valves.

As you can see on the image over, the "black" valve top right is the block valve and the bottom "black" valve is the bleed valve.

How a Single Block and Bleed Valve Works

A single block and bleed valve integrates two valve functions in one unit:

- A single block valve - This provides the main shutoff function, isolating the downstream part of the system

- A bleed valve - Located downstream of the block valve, this allows pressure to be released from the isolated section.

When you need to isolate a section of pipe:

- You close the block valve, creating a barrier between upstream and downstream sections.

- You then open the bleed valve, which vents any trapped pressure or fluid from the downstream side.

- This configuration confirms the isolation is effective - if fluid continues to appear at the bleed port while the block valve is closed, it indicates the block valve isn't sealing properly.

Unlike double block and bleed (DBB) valves, which have two block valves with a bleed in between,

the single block and bleed has just one block valve with a bleed port. It's simpler but still

provides verification that the block valve is functioning correctly.

These valves are commonly used in less critical applications where a single isolation point with verification capability is sufficient.

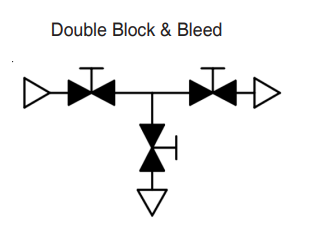

Double Block and Bleed (DB&B)

A Double Block and Bleed configuration consists of two independent block (isolation) valves with a bleed valve positioned in the cavity between them. This arrangement provides two separate barriers against process fluid, significantly enhancing safety through redundancy.

The typical components of a DB&B system include:

- Upstream block valve (first isolation point)

- Downstream block valve (second isolation point)

- Bleed valve (positioned between the two block valves)

- Cavity or chamber between the block valves

DB&B systems are commonly implemented in high-risk environments where the consequences of

isolation failure could be severe. They're often required by safety standards in

applications involving toxic, flammable, or otherwise hazardous materials.

DBBs are primarily used in the oil and gas, petrochemical, storage, and transmission industries.

How a Double Block and Bleed Valve Works

A double block and bleed (DB&B) valve system works through a specific arrangement of valves that provides verified isolation of process fluids.

Here's how it functions:

Basic Components:

- First Block Valve (Upstream): This valve serves as the primary isolation point from the source of pressure or fluid.

- Second Block Valve (Downstream): This provides a second, redundant barrier for isolation.

- Bleed Valve: Positioned between the two block valves, this smaller valve connects to the cavity between the block valves.

Operation Process

- Isolation Phase:

- First, the downstream block valve is closed

- Then, the upstream block valve is closed

- This creates a trapped section between the two valves

- Verification Phase

- The bleed valve is opened

- Any trapped pressure or fluid is released

- If the first block valve is sealing properly, flow from the bleed valve will stop after the trapped fluid is released

- Continued flow indicates a leak in the upstream valve

- Safe Working Condition:

- With both block valves closed and the bleed valve open, the system is in a verified isolated state

- This creates a "positive isolation" condition, allowing for safe maintenance

- Return to Service:

- After work is completed, the bleed valve is closed

- The upstream block valve is opened first

- Then the downstream block valve is opened

- The system returns to normal operation

What Is a Bleed Valve?

A bleed valve (also called a vent valve or drain valve depending on its orientation) is a critical component in block and bleed assemblies. This typically smaller valve serves several important functions:

- Pressure Release: It allows controlled release of trapped pressure from the cavity between block valves

- Media Evacuation: It provides a pathway to drain or vent trapped process fluid

- Verification: It enables confirmation that isolation has been successfully achieved

- Leak Detection: It helps identify leakage past the primary isolation valve(s)

- System Preparation: It assists in preparing systems for maintenance by ensuring zero energy state

Bleed valves are typically smaller than the main process valves because they only need to handle small volumes of trapped fluid. They are generally designed with safety in mind, often featuring mechanisms to prevent accidental operation or to ensure controlled release of potentially hazardous media.